Keep your aggregate equipment running like new

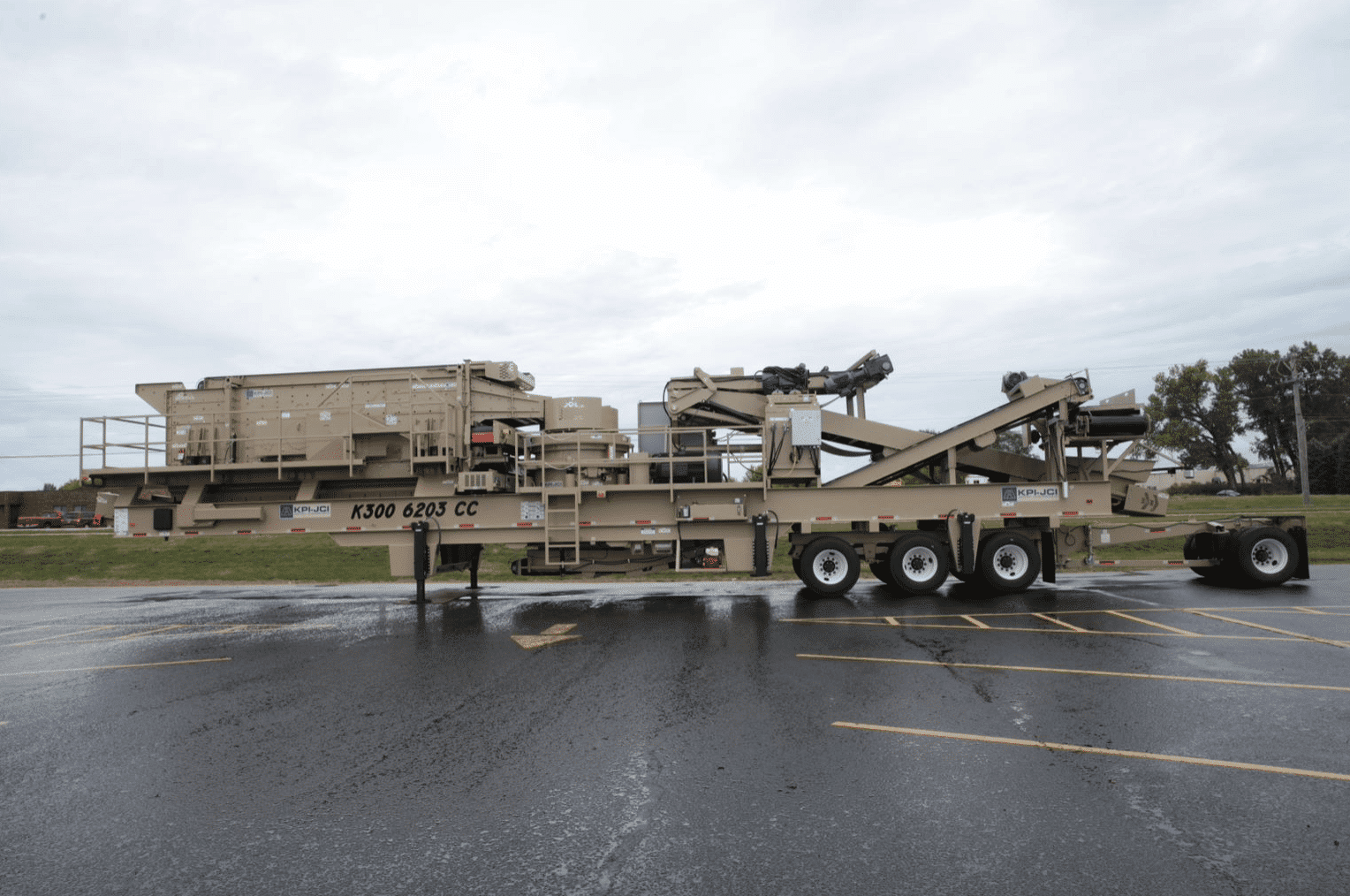

The aggregate industry relies on the uninterrupted operation of four heavy-duty aggregate equipment subsystems. This equipment supports the primary production processes of crushing, screening, material handling, and washing used to create saleable products. However, keeping your equipment up and running is a constant challenge, especially in the harsh operating conditions of aggregate production .

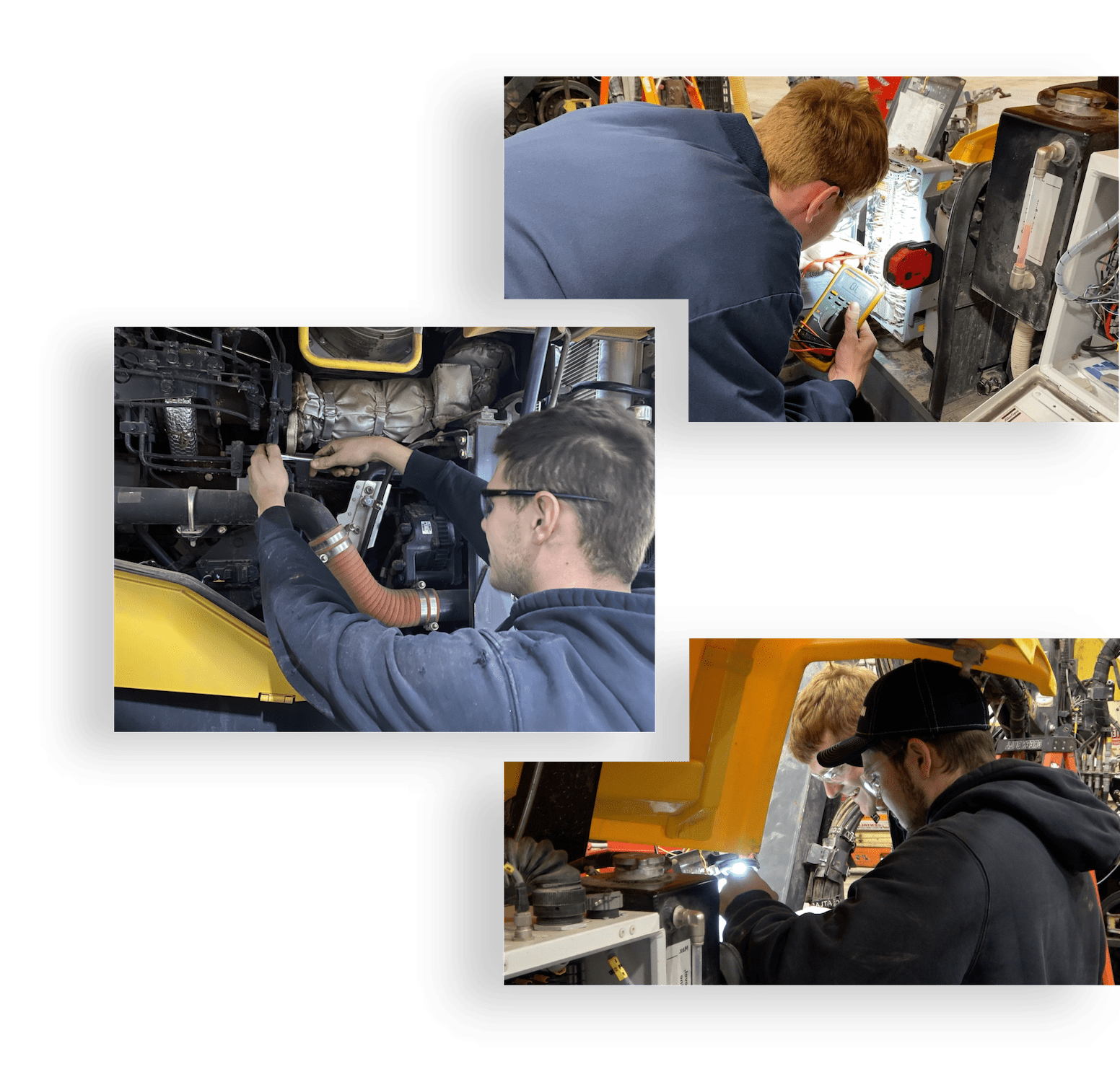

Reliable and properly functioning equipment is an RMS specialty. We are an aggregate solutions provider dedicated to keeping your equipment in tip-top shape, maximizing its uptime and usability well beyond the initial purchase. And because we service all manufacturers’ equipment, we are your one-stop provider regardless of where you purchase your equipment.